Steel, Stainless Steel or Aluminum ? How to Choose the Right Metal for Furniture (Without Regrets)

Choosing a metal for furniture sounds like a simple decision.

Steel.

Stainless steel.

Aluminum.

Three materials. Three price tags. Three strong opinions. And yet, this single choice will decide:

whether your product feels solid or flimsy,

whether it survives outdoors or ages badly,

whether production is smooth or painful,

and whether your margin lives or dies.

In short: this is not a cosmetic decision. It’s an industrial one.

First things first: there is no “best” metal

Let’s kill the myth right away. There is no superior material. Only materials that are right for a specific context.

If someone tells you “aluminum is better” or “stainless steel is the only serious option”, they are skipping the most important question:

What does this product actually need to do?

Now let’s look at the three candidates — without marketing clichés.

Steel: strong, honest, and unforgiving if neglected

Steel is the backbone of furniture manufacturing. It’s everywhere — and for good reason.

Why steel works

Excellent mechanical strength

Very good rigidity

Predictable behavior

Cost-efficient

Easy to bend, weld and assemble

Steel is perfect for:

structural elements

chairs, tables, frames

indoor furniture

high-use environments

Steel doesn’t pretend. If something works in steel, it usually works well.

Steel’s weak spot: corrosion

Steel has a single enemy: time + humidity.

Left untreated, it will rust. Always. That’s why finishes are not optional. At O-FLEX³, especially for outdoor furniture, we usually recommend:

galvanizing steel before powder coating it

Why?

galvanization protects the metal itself,

powder coating protects the surface,

together, they dramatically increase lifespan.

Paint alone is not enough outdoors.

It looks fine — until it doesn’t.

Steel is reliable, but only if you respect it.

2. Stainless steel: resistant, exposed, expensive

Stainless steel enters the conversation when corrosion resistance and visual presence matter.

What stainless steel does well

Excellent resistance to humidity and oxidation

No need for paint for protection

High-end appearance

Long lifespan in aggressive environments

It’s often used for:

outdoor furniture

hospitality and public spaces

kitchens, bathrooms, marine environments

visible structural parts

The price of “clean”

Stainless steel is not just steel with better manners.

It is roughly 4× more expensive than regular steel

Welding is more complex

Finishing welds is time-consuming

Every defect is visible

Stainless steel doesn’t hide mistakes. It puts them under a spotlight. It’s a premium material — and it demands premium execution.

3. Aluminum: light, modern, but not magical

Aluminum is often chosen for one word: weight.

Why aluminum is attractive

Very light

Naturally corrosion-resistant

Ideal for outdoor use

Easier handling and transport

Clean, modern appearance

It’s well suited for:

outdoor furniture

large pieces that must remain movable

repeated production

extrusion-based designs

contract

The reality check

Aluminum is not a shortcut.

It is roughly 2× more expensive than steel

It is mechanically weaker

It requires thicker sections for rigidity

It deforms more easily

Welding is technical and unforgiving

A badly designed aluminum chair feels cheap. A well-designed one feels effortless. The difference is not aluminum itself — it’s engineering.

4. What actually matters when choosing a metaL

Forget trends. Focus on constraints.

Indoor or outdoor?

Indoor → steel is often the smartest choice

Outdoor → aluminum or stainless steel, or steel with proper protection

Structural loads?

High load → steel or stainless steel

Light use → aluminum, if well designed

Visual intent?

Painted, discreet → steel

Raw, visible metal → stainless steel

Light, minimal → aluminum

Series size?

Small series → steel is usually simpler

Large series → aluminum can become efficient

Limited premium runs → stainless steel

Budget reality?

Steel = lowest cost, finish-dependent

Aluminum = ~2× steel, lighter logistics

Stainless steel = ~4× steel, premium expectations

The classic mistake

The most common error is choosing a material too early.

Before defining:

use conditions

structural needs

finishing strategy

production volumes

Material choice should be the result of industrial reasoning, not a stylistic reflex.

How we approach it at O-FLEX³

At O-FLEX³, we never start with:

“Let’s use aluminum.” or “Stainless steel will look better.”

We start with:

how the object will be used

how it must behave

how it will be produced

how it must age

Only then do we choose the right material. Because in furniture, materials don’t fail. Decisions do.

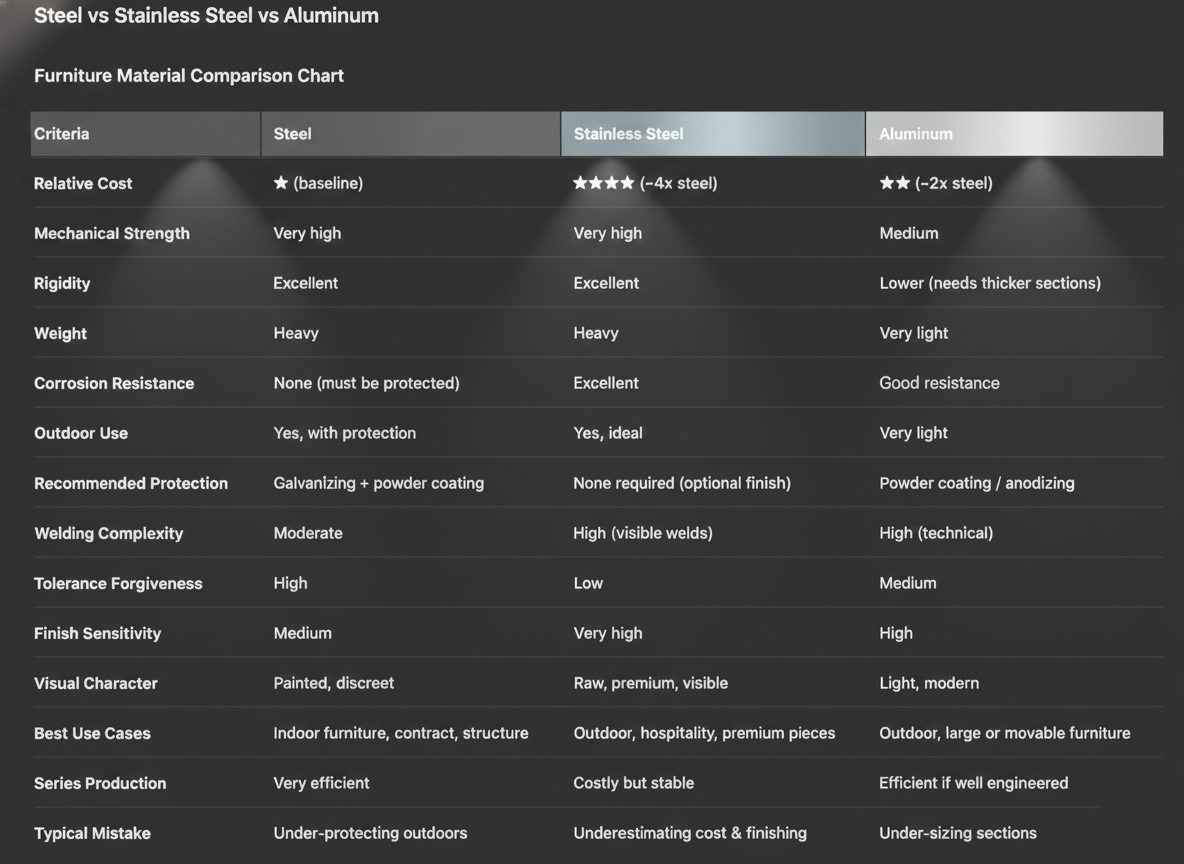

Summary of characteristics