How we work

Many furniture projects fail not because of design, but because of the gap between concept and manufacturing.

O-FLEX³ was built to address this gap. We support brands and designers by turning ideas into reliable furniture through technical validation, industrial development and in-house production. Acting as a single industrial partner, we help secure projects early and carry them through to manufacturing with clarity and consistency.

-

Is this idea technically viable ?

-

How can this furniture be manufactured properly ?

-

How do we turn plans into finished furniture ?

How a we develop projects at O-FLEX³

Every project follows three clear stages : Idea, plan, object

Each stage exists to remove a specific risk and move the project forward with certainty.

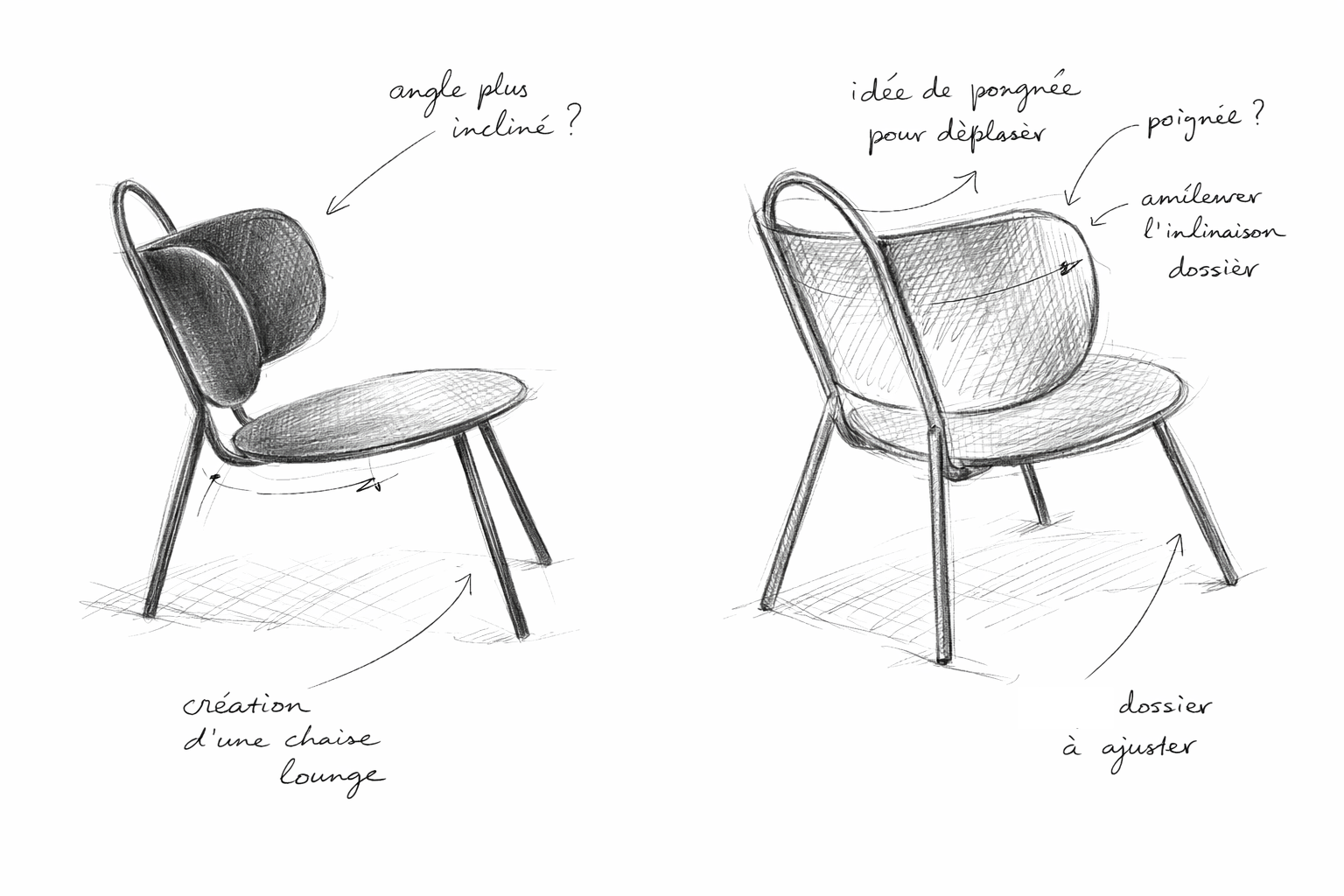

1. Technical validation

Securing the idea

The problem we solve

Many furniture ideas look right on paper but fail once they meet physical constraints.

Weak structures, unrealistic sections, unsuitable materials or impossible assemblies often appear too late — when time and money are already committed.

What we do at this stage

We test the idea against reality.

We check whether the design can stand, be assembled, and last over time. When needed, we adjust the design while preserving its intent.

What this gives you

Confidence that the idea is technically sound

Early decisions instead of late corrections

A concept that can safely move forward

Result

A secured idea, ready to be industrialized.

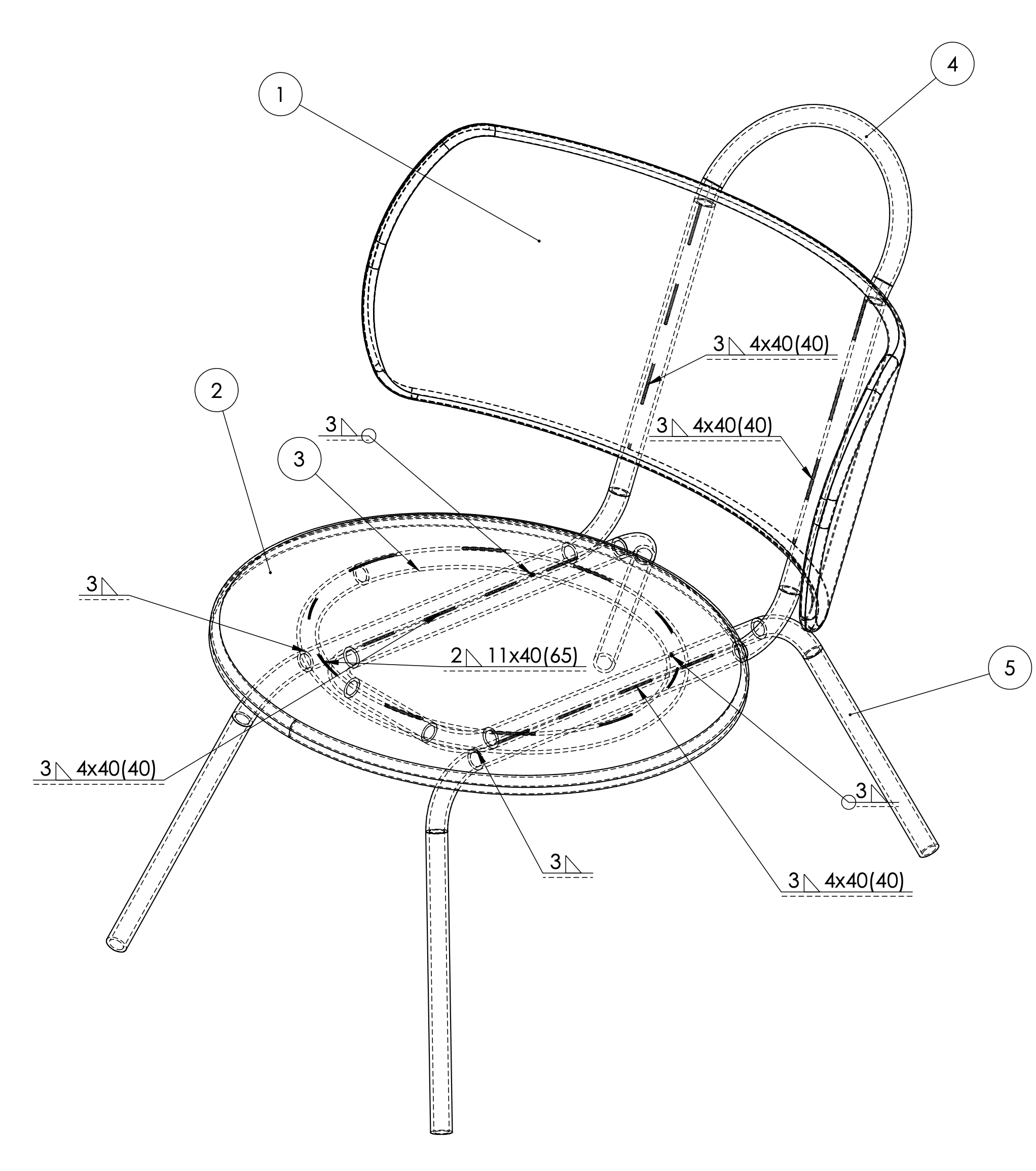

2. Industrial Development

Making the project producible

The problem we solve

A technically valid design can still be impossible to produce properly.

Without industrial thinking, costs explode, quality becomes inconsistent, and production turns into trial and error.

What we do at this stage

We define how the furniture will actually be made.

We adapt the design to real production constraints: machines, tolerances, sequences and finishes. Everything is prepared to ensure repeatability and control.

What this gives you

A clear and realistic production method

Controlled costs and lead times

A product designed for consistency, not improvisation

Result

A production-ready plan, ready to be manufactured.

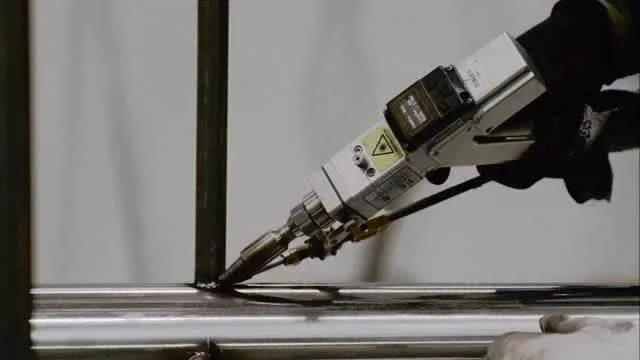

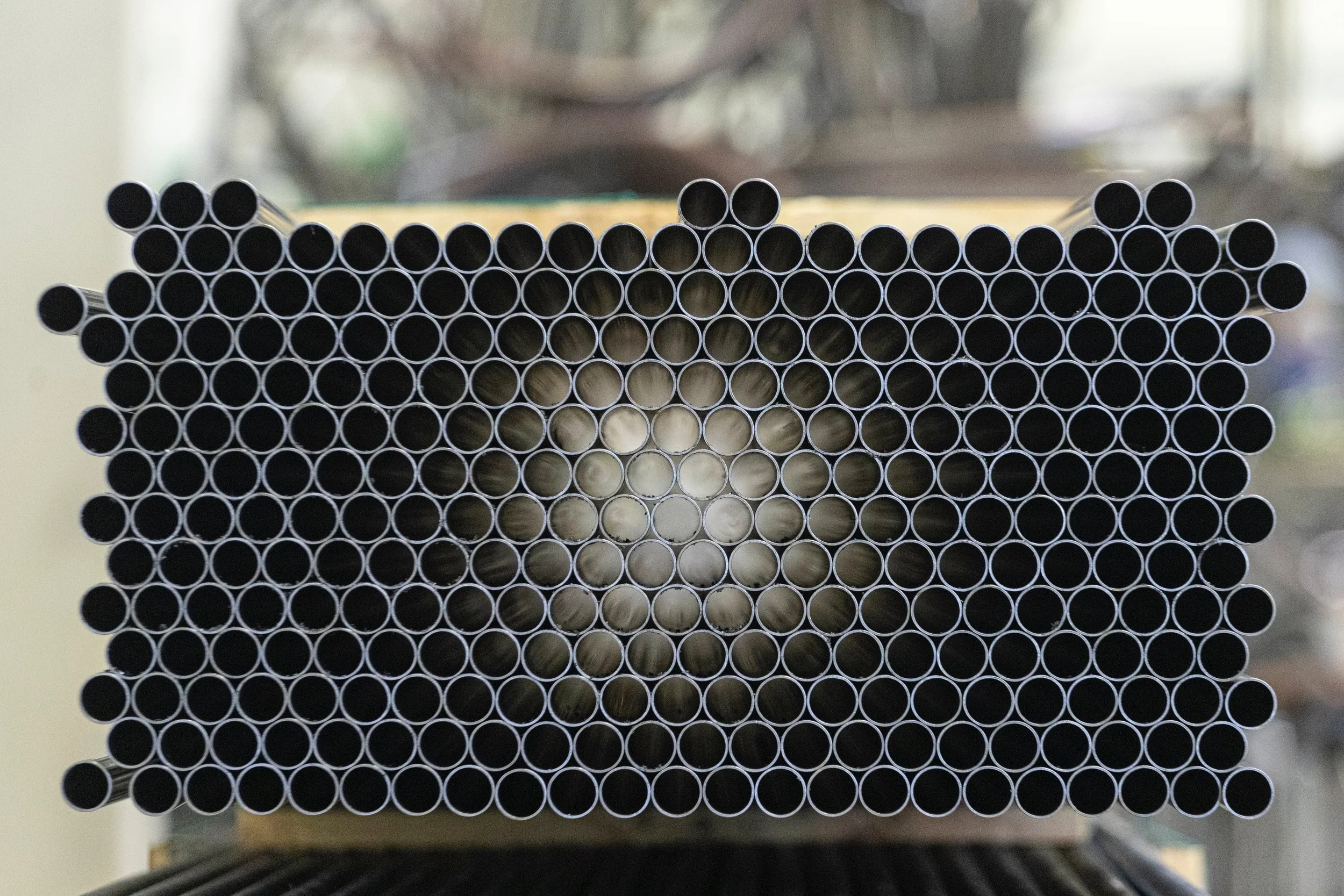

3. Production

How do we turn plans into finished furniture ?

With a validated industrial plan, we manufacture the furniture in-house.

Production follows the defined processes, with controlled quality, finishes and logistics.

This final stage turns the project into a finished, repeatable and reliable product.

Outcome:

Finished industrial furniture, ready to be delivered.

Explore our work on Instagram

Inside our processes